Choosing the correct grips and jaws can minimize variations and inaccuracies in tensile force measurements.

Fixtures must be chosen to ensure that the specimen is properly aligned, is rated to the correct force range, provides flexibility and interchangeability, and, of course, under no circumstances allows the test sample to slip. Regardless of the force tester used, selecting the wrong grips and fixtures will result in inaccurate results.

Grip choice considerations:

- Is the force capacity rating high enough for the test?

- Is the material to be tested sensitive to being damaged by the jaws of the grip?

- Does the material under test get thinner while being pulled?

- Are the correct jaws chosen for the material to prevent the specimen from slipping and also not prematurely going to damage the material itself?

- Is the grip weight and tensile force combined going to exceed the capacity of the load cell or force gauge.

- Does the test need to meet a specific ASTM or other standard?

- Is the grip connection compatible to the test stand and load cell? Is an adapter needed?

Grip Types for Tensile Strength Testing

Let's take a look at the most common grip types used in static tensile force testing. Also known as tensile strength testing, this method is used to determine the maximum pulling force that can be applied to a test object before it fails or fractures.

Wedge Action Grips are the most commonly used type of self-tightening grip. Self-tightening grips offer the advantage to continuously close tighter as force increase, to and minimize slippage of the specimen during a tensile test. Wedge grips achieve this by virtue of the fact that the two wedges are pulled together as tensile force is applied to the sample. This is especially advantageous during testing of materials that can elongate under tensile load, causing their diameter to decrease. Initial force can be applied by various methods such as side lever, capstan action wheel or screw.

Vice Grips are a type of manually-tightened grip which are ideal for flat specimens including plastic film, paper, sheet metal, fabrics and composites. Vice grips have a simple design, tightened via thumb screw or T-bar, offering cost advantages over more complicated grip types.

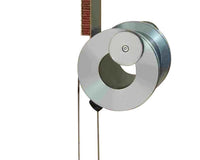

Eccentric/ Self-tightening Roller grips are another self-tightening grip, which are also well-suited to tensile testing of flat samples. Initial tightening is often performed by lever, and the serrated roller on the grips prevent slippage which is especially prevalent with malleable samples.

Jaw Face Type

Changing the jaw face pattern or grip surface is an easy way to further safeguard against slippage. Faces are interchangeable for different specimen material and dimensions.

- Serrated faces are well-suited for plastics, composite material, and metals.

- Serrated V-shaped jaws are ideal for testing large wire, rods, and tubing.

- Rubber coated jaws for softer materials such as films, thin sheets, bands, and paper